Technology of planting potatoes with a walk-behind tractor

The use of a walk-behind tractor when growing potatoes significantly increases labor productivity. Various operations for landing and processing crops become more technologically advanced and easier if you use a walk-behind tractor and additional attachments. As a result, one person will be able to cultivate large areas and get a solid harvest.

The features of working with walk-behind tractors, their technical characteristics and technological processes will be discussed further.

The content of the article

What is a walk-behind tractor

A walk-behind tractor or a motor-cultivator is a two-wheeled (but on the same axle) power unit equipped with a single or two-cylinder air-cooled internal combustion engine that provides the cultivator with traction during plowing, loosening, cutting furrows and hilling.

The motor cultivator is equipped with a lever steering wheel, with the help of which the operator following it guides it in the right direction. In addition, a trailer on a rigid axle is supplied to the power unit in the kit - when they are connected, a full-fledged vehicle of low carrying capacity is obtained.

The motor cultivator is equipped with a lever steering wheel, with the help of which the operator following it guides it in the right direction. In addition, a trailer on a rigid axle is supplied to the power unit in the kit - when they are connected, a full-fledged vehicle of low carrying capacity is obtained.

The use of a walk-behind tractor significantly increases labor productivity in comparison with manual digging or hilling. However, performance is directly related to the power of the power unit - according to this indicator, no walk-behind tractor can be compared with a tractor.

Growing technology potatoes is a sequence of different types of land cultivation.

Walk-behind tractor landing rules

When the ground warms up not less than + 12 ... + 15 ° С, it can be started to cultivate... To do this, instead of wheels, disc cutters-rippers are installed on the walk-behind tractor. Further, these cutters process the entire area. One of the cutters (for example, the left one) should follow the trail left by the right one during the previous strip. Then the site will be properly loosened by depthcorresponding to one spade bayonet.

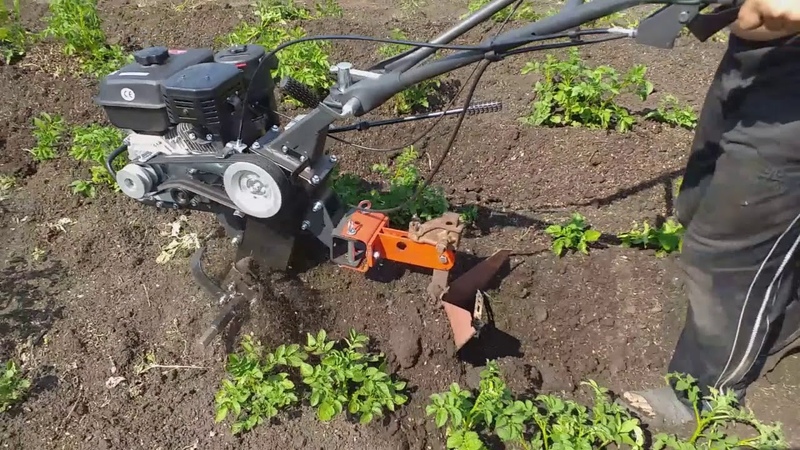

Then the furrows are cut. To do this, you will need two-row hillers, which are installed on a special suspension behind the wheels. Disk cutters in this case are replaced with metal lugs. Riggers are designed to cut 65 cm furrows - that is, they provide just the kind of furrow spacing required for growing potatoes.

After that, tubers are placed in the prepared furrows.... It is advisable to place them in a checkerboard pattern (relative to adjacent furrows), and the distance between the potatoes should be 40-45 cm.

When the seed is spread out, it is covered with soil. To do this, set the hooks so that they go along the tops of the beds. In addition, the hillers are adjusted to maximize their working width. When passing the beds, the walk-behind tractor will cover the potatoes with earth. If done correctly, the planted field will be a smooth surface.

Plowing technology

The most common cultivators of the following brands:

- Motoblocks "Neva". Gasoline engine power - 6.5 liters. from. (4.4 kW), engine displacement - 196 cm3, weight - 85 kg, processing depth - up to 200 mm.

- Motoblocks "Salute". Gasoline engine power - 7 HP from. (5 kW), engine displacement - 208 cm3, weight - 70 kg, processing depth - up to 320 mm.

- Motor-cultivators of the Minsk Tractor Plant - in particular, the Belarus-09N model. Gasoline engine power - 9 HP from. (6.6 kW), nominal pulling force - 100 kgf, weight - 176 kg, processing depth - up to 300 mm.

Planting methods

Depending on the initial state of the earth, several subtleties of planting potatoes with the help of walk-behind tractors are distinguished.

Working with a hiller

A hiller is an agricultural equipment for working with soil, whose purpose is to take soil from the bottom of the furrow and move it to the sides and up. Hillers are symmetrical - unlike the plow, they lack a pronounced blade.

With the help of hillers, the primary cutting of the furrows, the filling of the planting potatoes with soil, as well as the hilling itself, when the beds acquire their final appearance, and space for new tubers is added around the root system of the plant, are performed.

Hillers are single-row and double-row... They are installed on a special console behind the wheels of the walk-behind tractor. The total productivity depends on the number of rows processed. More rows - faster processing. However, this increases the complexity of the operator's work. For this reason, it is advisable to install double-row hillers if the soil in the field is sufficiently developed.

Hillers have a fixed or adjustable working width. Experienced farmers advise purchasing an adjustable grip tool to adjust the furrow width. In addition, the hiller can be used both for the formation of furrows and for covering the tubers with soil.

Working with disc cutters

They are installed instead of wheels, while the speed of their rotation is not directly proportional to the speed of movement of the walk-behind tractor.

The cutters scroll through the soil, loosen it and it is saturated with oxygen. However, you can use cutters only if the ground is loose. Otherwise, the cutters simply "will not break through" deep into the soil layer.

Landing under the plow

The plow is used in those cases when it is necessary to cultivate either virgin soil or dense soil. Plowing is the most difficult part of the cultivation process for the operator, as it requires a lot of effort. The tiller in this case will move at the lowest speed.

Important. After the initial plowing, it is not necessary to cultivate the land with disc cutters.

If plowing is done carefully, then additional cutting of furrows may not be necessary. Then, to cover the tubers with soil, change the plow to a single-row hiller.

Planting a mounted potato planter

For this, special hillers are used, consisting of the following elements:

- Conveyor Is a conveyor whose task is to supply the seed to the place of placement.

- Furrow former (or furrower).

- Distributor - is responsible for ensuring that the tubers fall into the furrows at strictly defined points in time. Thus, the uniformity of their sowing is maintained.

- Hiller - with its help, the tubers are covered with soil.

For a start, lugs are installed on the walk-behind tractor, as well as a special bunker where they fall asleep tubers for planting. Further:

- Furrows are formed by lugs.

- The seed from the hopper goes through the conveyor and the distributor into the furrow.

- Then the lugs are changed to rubber wheels (so as not to damage the seed), and instead of a hopper with a distributor, hillers are placed on the walk-behind tractor. The cultivator moves along the beds, and the hillers cover the decomposed potatoes with soil.

Using a mounted potato planter speeds up planting, saves time and effort.

Process technology

The garden is marked out so that the beds are as long as possible - then it will not be necessary to unfold the walk-behind tractor often. Technological map of planting potatoes is as follows.

First, the field is prepared for furrowing.

There are two options:

- or they perform its primary plowing with a plow, and then the furrows will not need to be cut;

- or the soil is loosened with disc cutters, then furrows are formed.

Then, in a checkerboard pattern (in increments of 40 cm), the seed tubers are laid.

Further, the tubers are covered with earth from the formed beds with the help of hillers.

A standard plow or hiller is capable of "deepening" by 20 cm. This means that the formed beds will have a depth of 30 to 40 cm. When the tubers are covered with soil, the planting depth will automatically be 20-25 cm.

Crop care

After the potatoes sprout - approximately on the 35th day, it is hilled. To do this, use standard hillers (preferably with an adjustable working width). The hiller lifts an additional at least 10 cm of soil from the bottom of the bed and rolls onto its walls, which gives additional volume for the formation of new tubers.

Important. At the same time, the hilling process will lead to suppression of the development of weeds - young shoots of potatoes will gain an advantage over them, begin to develop faster and shade them, preventing them from growing.

However, if the weeds in the field develop more actively than the vegetable, then the potatoes are weeded before hilling. For this, a mounted mesh harrow is used.

Also, a motor-cultivator significantly simplifies the process of spraying potatoes (for example, with chemical compounds against the appearance and development late blight). To do this, a tank and a sprayer are installed on the walk-behind tractor. The process can be completed literally in one pass without significant physical effort.

Harvesting with a walk-behind tractor

To harvest potatoes, a plow is installed on the walk-behind tractor. Its end will go into the ground deep enough to take the soil along with the new tubers to the dump and turn them over, leaving them on the surface. Then it remains only to harvest the crop.

Tips and tricks from experienced gardeners

A motor-cultivator is a means of small-scale mechanization, which serves to save the strength, energy and health of the gardener... Therefore, you should not hang two hillers: it will become much more difficult to control the walk-behind tractor. As a result, it may be easier to plant the potatoes in the usual way.

After plowing virgin land, it is recommended to change the lugs to cutters and cut the soil. This will loosen it, facilitate further covering the potatoes with soil and hilling.

Conclusion

The walk-behind tractor is a technological, compact and inexpensive tool for small-scale mechanization, which, moreover, can be used as a traction unit. Moreover, walk-behind tractors are designed specifically for processing small and medium-sized land plots. And their use greatly simplifies the cultivation of potatoes.