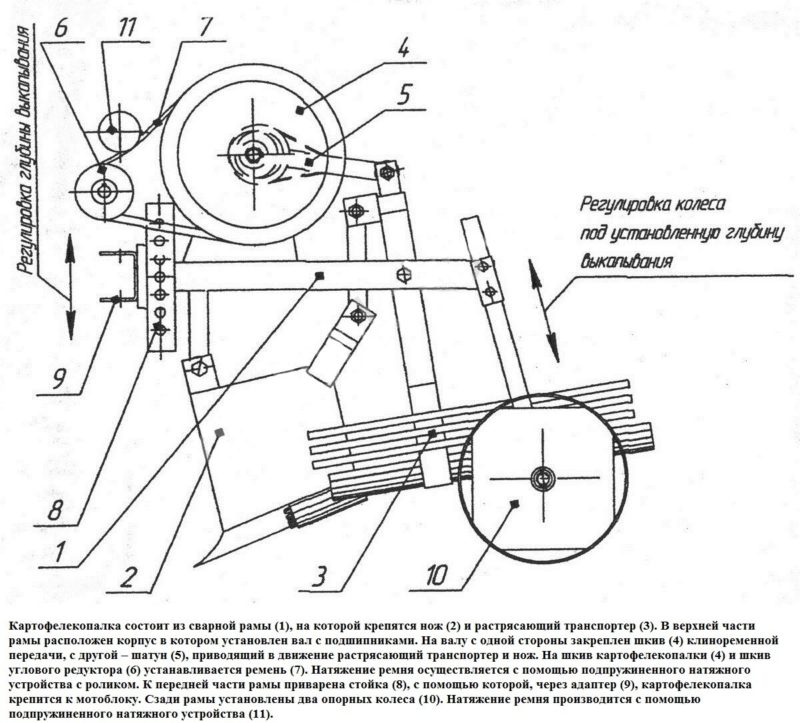

How to make a potato digger with your own hands: step-by-step instructions from A to Z

A quick potato harvest is important not only for farmers, but also for owners of personal plots. To speed up the energy-consuming process, many gardeners have mastered a universal attachment - a potato digger, made on their own. Factory counterparts are not cheap, so we recommend making a simple and effective unit with your own hands.

The content of the article

What is a potato digger

The growing popularity is gained by the potato digger for walk-behind tractor - a common vehicle on a personal plot. To perform various works, attachments are installed on it. One of its most popular types is the potato digger.

This device allows you to separate the potatoes from the ground and throw them onto the ground without damaging them. It remains only to collect the tubers in a suitable container. The mechanism is used both in large farms and in small areas.

Factory goods are expensive: prices range from 6.5 to 13 thousand rubles. There are also cheaper Chinese-made models on trading floors, but their quality is questionable. Therefore, it makes sense to start making a potato digger for use on small cultivated areas.

Craftsmen who have tried home-made equipment in practice speak of many of its advantages:

- Ease of use.

- Increase in labor productivity.

- Selection of the design dimensions suitable for the farmer's application.

- The ability to sharpen rods for the characteristics of your soil, as well as for a specific model of a walk-behind tractor.

- Good harvesting speed - it is possible to select tubers on an area of 0.1-0.2 hectares in 1 hour.

- Optimization and relief of physical activity.

- Gentle extraction of tubers from the ground.

- Significant cost savings.

- The ability to use for digging other root crops, cultivating soil in the garden and in the garden.

The only drawback is that a homemade digger will only be effective on light to medium-heavy soil.

What does it look like

The attachment has a simple design, so making it yourself will not be difficult.

Attention! The digger is used in an area cleared of grass and tops, otherwise the fasteners and grate will quickly clog.

Outwardly, the device resembles an ordinary wheelbarrow on wheels, but differs in the presence of teeth and mechanisms for rotating the conveyor belt. It is also equipped with an element for fixing to a walk-behind tractor or mini-tractor.

Consists of:

- Frames.

- Elevator for transporting potatoes. It is a grid or lattice that serves to clean the tubers from the ground. Supplied with side walls to prevent potatoes from falling out.

- Shafts that vibrate the grate.

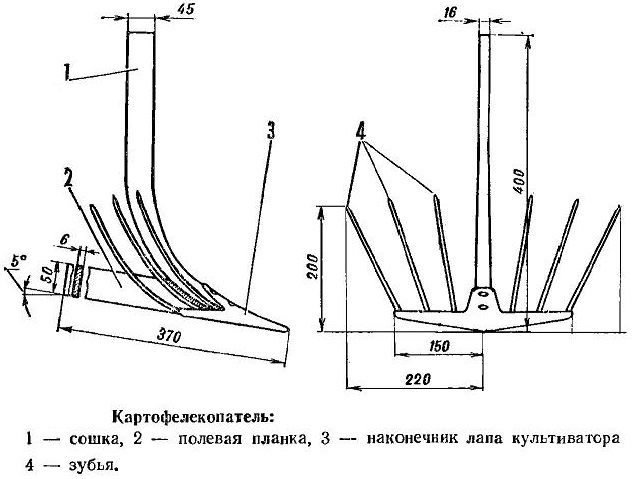

- Plow with knives (ploughshare).

- The supporting mechanism that drives the structure. It includes wheels, bearings, hubs, chains, etc.

Principle of operation

A potato digger for a walk-behind tractor helps to extract not only potatoes from the ground, but also beets, carrots, onions, and garlic. It works like a shovel or plow, but teeth or rods are welded to the parts.

It happens as follows:

- The plow sinks into the ground to a depth of 20 to 50 cm.

- When driving, the walk-behind tractor pulls out the tubers along with the soil, after which the mixture falls on the grate.

- On it, the earth is sifted through vibration, and the peeled tubers fall into the container. There may not be such a collection, then the potatoes will fall to the ground. After that, it is enough to walk across the field and harvest.

Compared to a shovel, a potato digger significantly reduces the consumption of physical strength.

Reference. This kind of technique allows you to avoid damage to the tubers and to harvest accurately. If the surface of the vegetable is slightly scratched, it is better to eat it right away.

Types of potato diggers

There are 2 types of potato diggers on the market:

- passive;

- active.

Attachments are passive, which have a simple design and low cost. Such devices are called lancet, fan-shaped, or simple. The main working element is a shovel, on which rods are welded.

This is a very reliable piece of equipment, but it has poor performance. In addition, approximately 15% of the crop remains in the soil. Other negative aspects include high fuel consumption and shallow digging depth (15 cm). The capture width is 20 cm. Such a device is fixed on a cultivator or walk-behind tractor.

Active potato diggers are divided into the following types:

- conveyor;

- vibrating (roaring).

Vibrating potato diggers work thanks to the share and the vibrating table. The design is improved by connecting the mesh. The device is equipped with one or two eccentrics.

Conveyor models are divided into belt and conveyor models. Their main difference from other models is the presence of a belt on which the soil with potatoes is sifted. Fuel consumption of such models is minimal, and the harvesting percentage reaches 98%.

There are also drum potato diggers. They are used in large areas. The device consists of 3 main elements:

- knife;

- frames;

- a rotating drum, which is made from steel rods.

The knife is attached to the frame with a pivot joint. He cuts the soil layer along with the potatoes. As the drum rotates, clods of earth break up and wake up through the grate, and the tubers fall out onto the arable land.

Which is better

There are many popular models. Before making a final decision, it is important to decide on the following parameters:

- The area of the cultivated area. The power of the technique depends on it.

- Soil quality. The simplest equipment cannot handle hard ground.

- Humidity. Cheap and low-power potato diggers do not work well with wet soil.

- Dimensions of the device. The wide ones are used on large plantations, and the narrow ones are used in vegetable gardens for single beds.

- Type of cleaning potatoes from the ground. Different models of potato diggers purify clay, loam, black soil, sandstone in different ways.

- The presence of additional elements, such as wheels.

- Fastener type.

- The cost of the apparatus.

- The condition of the main equipment, i.e. a walk-behind tractor or a mini-tractor. Modern attachments are often not suitable for outdated models.

What type of potato digger can you make yourself

The most suitable type of potato digger for self-production are vibration-type devices.

It is a versatile mechanism that is used for small to medium sized areas. Plus, it's not hard to do. For large fields, it is better to choose a drum type potato digger.

It is interesting:

Device for sorting potatoes and how to make it yourself

How to make a potato hiller for a walk-behind tractor with your own hands

How to make a shovel for digging potatoes with your own hands

How to make a potato digger with your own hands

It's easy to make a device yourself. The main thing is to adhere to the algorithm of actions, to prepare all materials and drawings.

Required materials and tools

To make a vibration-type device, you will need special tools and equipment.

Required tools:

- welding machine;

- Bulgarian;

- drill and drill;

- heavy hammer or sledgehammer;

- a set of keys;

- square;

- calipers;

- level.

After collecting the tool, prepare the following materials:

- steel sheet with a thickness of about 8 mm;

- metal profile (channel No. 8);

- steel rods or reinforcement with a diameter of 10 mm;

- a pipe for the manufacture of racks;

- corner;

- bolts, nuts and metal plates for fasteners;

- roller chain;

- wheels.

Diagrams and drawings

It is important to prepare a drawing of the future device in advance. The easiest way is to use a ready-made one. Below are some examples of schemes of different types of potato diggers.

Step-by-step instruction

Step-by-step algorithm for assembling a potato digger:

- The frame is made. It is welded from a corner with dimensions 63 by 40 mm and channel No. 8. Frame length approx. 120 cm.

- At a distance of 1/3 from the beginning of the frame, the first channel is welded, and the second - at a distance of 1/6 from the front edge. These channels will serve as the base for attaching the element designed to adjust the digger.

- On the sides of the frame, metal racks are welded vertically to the ground at a distance of 10 cm from each other. Their length is different. They start with 50 cm, then 40, 30, etc. The base for the lattice will be welded onto these posts.

- Channels are welded to the shortest racks so as to obtain 2 rigid triangles on which the share will be fixed.

- A 30 mm wide plate is cut from a sheet of metal and welded to one of the triangles. After cooling, it is bent and screwed to another triangle with bolts.

- For the manufacture of a ploughshare, an old plow, metal plates or a pipe with a section of 200 mm, cut lengthwise, are used. The workpiece is bent like a plow and rounded sharpening is performed. The ploughshare is fixed to the elevator casing with bolts.

- Metal rods are cut. The length is selected so that on the one hand they are welded to the plate, and on the other they protrude beyond the frame. The rods are welded at a distance of 4 cm from each other.

- A metal bracket is welded to the free ends of the rods, which is made from a pipe or strip. To ensure the mobility of the bracket, it is attached to the swivel joint.

- If necessary, the elevator is replaced with a cleaning drum. It is made in the form of a half-cylinder from reinforcement and metal strips.

- Now a reduction unit is being mounted, with the help of which the inclination of the elevator and the share will be changed. The reduction unit is attached to the slider rod on bearings.

- The sprockets are used to secure the connecting bridge rod. Metal discs are welded onto it from both sides and wheels are attached.

This completes the manufacture of the potato digger. It remains to fix it on a walk-behind tractor or mini-tractor and make a test run.

Attaching the potato digger to the unit

Method of attachment to the walk-behind tractor:

- They start with the preparation of the walk-behind tractor. Remove the protection from the power take-off shaft. Take out the locking pin from the hitch.

- A half cardan is put on the input shaft of the potato digger gearbox.

- The device is attached to the trailed unit of the walk-behind tractor. Fix with your finger.

- At this stage, the operability of the driven and driving shaft is checked. To adjust the alignment, use the adjusting bolts on the trailer unit.

- All threaded connections are fixed with locknuts.

One of the most important steps is adjusting the half cardan length. It is installed so that there is a gap of 5-10 mm relative to the gearbox.

To connect to a mini-tractor, you will have to purchase a special mechanism designed to connect a potato digger as an attachment.

Useful tips on the topic

Useful tips that will come in handy when making and using a homemade potato digger:

- To bend a metal plate or other element of the device, it is first heated with a gas burner. After obtaining the desired shape, the part is tempered.

- It is advisable to prepare a drawing of the device and all significant nodes in advance.

- For beginners, it is recommended to first transfer all dimensions from the drawing to cardboard and assemble the model. Only after that start cutting the metal. This technique helps to visually see all the problem areas.

- During testing of the finished device, a test run is made. It is enough to travel just a few meters to see how well or poorly the potato digger works. If necessary, change the angle of inclination and immersion depth.

- Correct device setup maximizes performance.

Conclusion

Any type of potato digger allows you to speed up and facilitate work in the field or in the garden. By self-production, the farmer saves a large amount.

In order for the device to be of high quality and to cope well with its tasks, it is important to use drawings. This reduces the likelihood of errors at different stages of work.