What is the Falling Number for Wheat and how is it determined

The quality of the grain is extremely important for the type of flour. There are certain indicators that help agronomists calculate the class of wheat and the variety of the future flour product. Grains are distinguished by composition and fall number. The latter is regulated by GOST standards, while laboratory equipment is used for correct calculation. Read more about the fall number below.

The content of the article

What is the Falling Number of Wheat Grain

Falling number (NP) is a key criterion for the distribution of harvested grain by class... It displays the value of the activity of the substance alpha-amylase, which characterizes the baking properties of flour.

The value can increase dramatically with grain ripeningif storage is not in accordance with standards or harvesting is not on time. Unfavorable weather conditions (rain, high humidity, fog) also affect the falling number.

Metric calculation technology

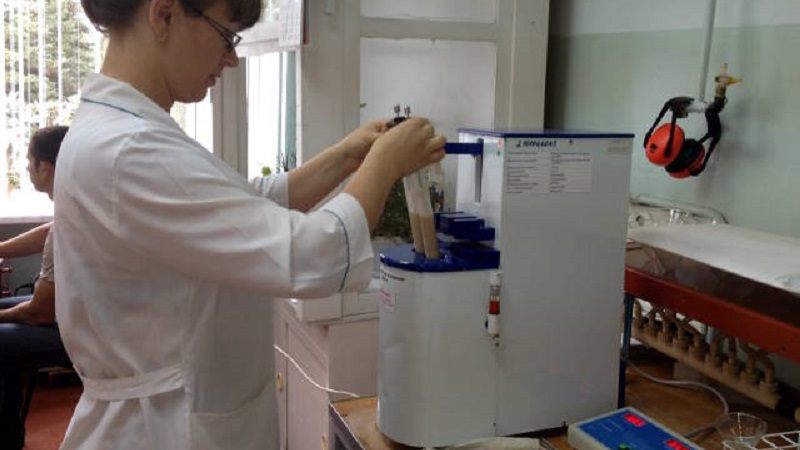

Agronomists use special equipment to track emergency situations... In addition to the falling number value, such devices monitor the temperature of the water.

Important. The sequence of actions must comply with GOST 27676-88 “Grain and products of its processing. Falling number determination method ".

According to GOST, the assessment of the state of emergency takes place in three stages:

- training;

- mixing;

- analysis.

The first two stages are performed by a person, the last is determined by the device (PPP).

Training

To begin with, about 300 g of wheat are taken from the grain storage... In this case, the moisture content of the crop should not exceed 18%, otherwise the grain must be dried.

The cleaned sample goes through the grinding and sieving stage... Then, using a laboratory balance, 7 g are taken from the total volume.

Interesting on the site:

Optimal conditions for wheat growth

What is the yield of wheat from 1 ha and what does it depend on

Mixing

Flour is poured into a test tube and 25 ml of water at room temperature is poured (necessarily distilled). The next step - mixing until smooth - can be done either manually or using a special shaker.

Analysis

A dedicated device (PCP) must be prepared in advance (the temperature of the water bath must reach 100 ° C).

A dedicated device (PCP) must be prepared in advance (the temperature of the water bath must reach 100 ° C).

The test tube is placed above water, after about 4-5 seconds, the PCP begins to automatically shake. After 1 minute, the device stops mixing, and the already thickened mixture sinks under the weight of its weight.

SP is the length of time from the start of agitation to the final vertical position. The value can be rounded, but the difference between the obtained result and the rounded one should not exceed 10%.

What determines the reliability of the result

The accuracy of the result directly depends on compliance with the standards when measuring the indicator... Of course, it is impossible to completely avoid the slightest errors, but sometimes there are large deviations in the value of the NP.

Both the technical side and the human factor affect the accuracy... The latter includes:

- Improper performance of grain grinding.

- The percentage of humidity is not taken into account (exceeds 18%).

- Deviation from water temperature.

- Inaccurate scales for laboratory analysis.

- Insufficient manual agitation.

- The water bath has not reached the boiling point.

- Immersion in PWYP is abnormal.

Falling number as an indicator of protease activity

The baking properties of rye flour are determined by the amount of starch... And the characteristics of wheat depends not so much on starch as on the quality of gluten proteins.

PE shows amylase activity: by analyzing it, you will know the activity of other important enzymes, for example, proteases. The relationship between the two substances is direct. If the amylase activity is high, then the protease index will be increased. If the value for amylase is reduced, then proteases also show low activity.

The breakdown of gluten depends on proteases, which is so valuable for a flour product. A high level of activity destroys it.

Read also:

Top dressing of winter wheat: methods and application rates

How Wheat Falling Number Affects Bread Quality

Since the end product of grain is often bread, the state of emergency directly affects its quality... The measurement of indicators takes place in a second ratio.

Low rates

The lowest possible values are prescribed in GOST:

- not less than 185 (for extra and first grade);

- not less than 160 (for the second grade).

If the state of emergency is below standard indicators, then bread from such flour will move away from the crust and have a sour taste... The pronounced smell of malt and the unstable shape of the product are also characteristics of bread made from low-quality flour with a low falling number.

Flour improvement is quite possible, the quality is increased by the addition of ascorbic acid or calcium peroxide. These substances visibly thicken the gluten and affect the quality of the finished bread.

High performance

A baked product made from flour with a high falling number is also not considered good quality.... This bread is characterized by:

- freshness;

- pallor;

- unpleasant odor;

- dryness;

- small volume.

A high PR indicates that the activity of wheat's own substances is reduced, but this is an important condition for a high-quality fermentation process. Large numbers indicate improper drying of grain, most often at high temperatures, which is unacceptable.

Optimal value

Both high and low values are undesirable for finished bread... The value should be optimal and strictly comply with GOST.

Important. GOST 52189-2003 prescribes the necessary values, but only the boundaries of the lower indicators are given there.

What should be the falling number according to GOST

A falling number of 230 is considered a good indicator.... The value may vary slightly (± 15). With such an emergency, the bakery product is airy with a pleasant smell. The color of the bread is not dark, as in low rates, and not overly pale, as in high HR.

What determines the indicator

When measuring indicators, take into account:

- weather;

- place of growing wheat;

- grain grade.

Wheat from different fields can be brought to the granary, which is wrongas it leads to low or high falling number results. Grain is harvested in warm and dry weather. Mixing of different types of grain should not be allowed. Even a small percentage can greatly worsen the value of the NP.

Pay attention to harvesting equipment, it must meet quality standards.

Also control of post-harvest ripening is important... The granary should be equipped with special equipment for automatic drying of grain and fans. The indoor air must be dry. An excellent solution would be to automatically monitor the temperature in the elevator.

Grain is dried in several stages in order to avoid excessive overheating, to preserve the embryo and the enzymatic composition. Storage moisture should not exceed 14%.

Multivariate express analysis will make it possible to produce a calibrated infrared analyzer of grain and processed products (meal, cake, cake).

Conclusion

In order for the resulting product to meet the standard and quality, it is required to properly grow wheat and monitor important indicators prescribed in state standards. It is necessary to carry out the analysis strictly in laboratory conditions. In order to avoid errors, it is recommended to use advanced PR instruments.