The advantages of a manual potato digger and how to do it yourself

Harvesting is troublesome and laborious. Removing potato tubers and various root crops from the ground by hand involves a lot of physical effort, which somewhat darkens the joy of getting a good harvest. Therefore, large farmers and amateur gardeners use various devices. Tractors and monoblocks are used on huge areas where it is easy for machinery to turn around. In small gardens, they dig potatoes with a hand-made homemade digger.

The content of the article

What is a potato digger

Different versions of this device allow, while unloading some parts of the body, load others, stronger and more resilient. This makes work easier and increases productivity. Almost all designs of manual potato diggers are available for making at home.

Reference. With all the variety of design solutions for manual potato diggers, almost all of them are based on two main principles: rotational and lever.

Device types

These devices based on the rational use of the muscular strength of the arms, legs and back of the vegetable grower are in the form:

- "American" - a combination of a bayonet shovel with a shovel;

- the "Tornado" tool based on the rotational actions of human hands;

- pivoting forks, when, like a lever, the main efforts are transferred from a person's arms and back to his legs.

There are many modifications inside these basic types of manual potato diggers., depending on the design abilities of the gardener, his technical and material capabilities.

Description

A manual potato digger in the form of a shovel ("American") looks like an ordinary bayonet shovel with the only difference that her canvas is somewhat deepened like a soviet. As a result, the tool not only cuts the ground, but also captures a large volume of soil with potato tubers with its surface.

Reference. "American" are distinguished by the fastening of the handle, which makes a smaller angle with the blade than that of a shovel, but does not run parallel to it, like a bayonet. This design is most rational when harvesting vegetables.

The Tornado manual potato digger popular with farmers does not look like a shovel... It is a sharp pin at the end of the handle, next to which are curved, long and sharp teeth. The pin digs into the ground and the horizontal T-handle with curved handles rotates 90 °. The teeth go into the soil and bring the tubers to the surface. During operation, the device allows you not to bend over or strain your lower back.

Various modifications of rotary forks are even more in demand among vegetable growers.... Thanks to the lever principle, they redistribute the main efforts when digging potatoes from hands and back to legs. The teeth of the device pierce the ground and raise the tubers to the surface.

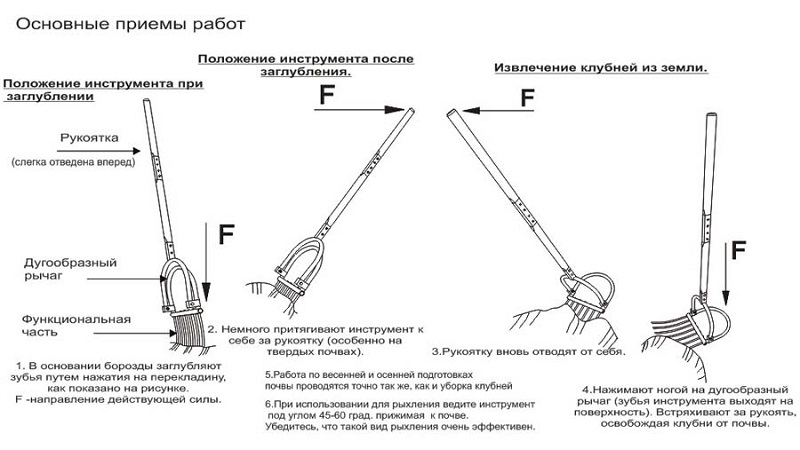

The algorithm for working with such a potato digger is simple:

- The tool is driven into the soil next to the potato bush.

- One of the legs is pressed against the arc, completely burying the teeth into the ground.

- The handle on the right or left is tilted as low as possible.

- The handle is returned to an upright position.

- One of the legs is pressed against the formed lever.

- As a result, the pitchfork rises up, extracting tubers from the ground. At the same time, the soil crumbles between the teeth.

Besides that such a potato digger reduces the load on the arms and back, it also takes good care of the vegetables themselves, because it undermines them from the side and bottom.

Interesting on the site:

Instructions for creating a homemade potato planter

main parameters

The parameters of a manual potato digger directly depend on its design.... The simplest of these, the popular rotary forks, has a gripping range of 0.3 m and an average weight of about 3 kg. For its manufacture, high-strength steel is used. The teeth are made from metal rods with a diameter of 15–20 mm of a round, square or hexagonal section, the handle is made of wood.

Important! Since a device made of metal and wood often has to come into contact with moist soil, it is stored in a dry room.

Advantages and disadvantages

The advantages of manual potato diggers include:

- increasing labor productivity;

- optimization and relief of physical activity;

- sparing attitude towards potato tubers when removing them from the ground;

- the possibility of using them for digging other root crops, cultivating the soil in the garden and in the garden.

A significant, but only drawback of such hand-held devices is the need to exert physical effort.

Additional functions

Potato diggers are not only used for harvestingbut also for planting plants. They are suitable as a cultivator for loosening the soil, getting rid of weeds and applying fertilizers to the soil.

Which is better: "Tornado" or "American"

"American" is an improved, but still a shovel, it has all the disadvantages of an ordinary bayonet shovel... They are aggravated by the greater load, which is created due to the deepening in the canvas. In addition to straining the arms, legs and back, you have to constantly bend down to the ground in order to extract potato tubers from the earthen clod.

The Tornado manual potato digger is spared most of these shortcomings.... With it, you do not need to bend over either during work or to extract potatoes from the soil, since the soil is removed through the tines.

How to make a potato digger with your own hands: step by step instructions and drawing

A craftsman who knows how to work with metal and has a welding machine can independently make an effective manual potato digger.

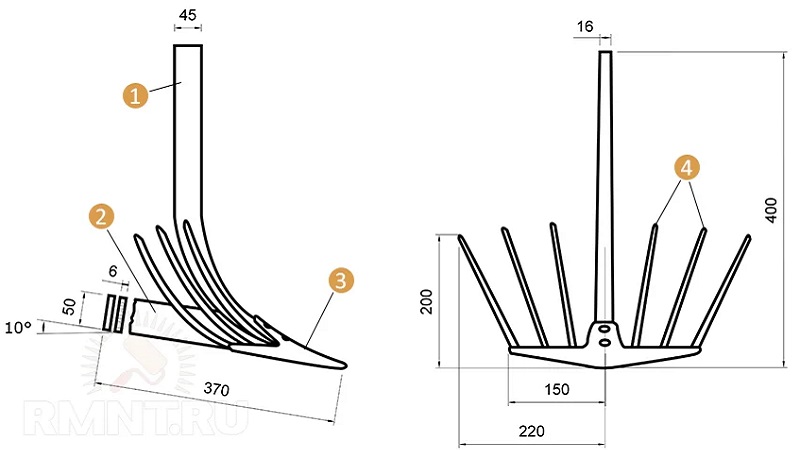

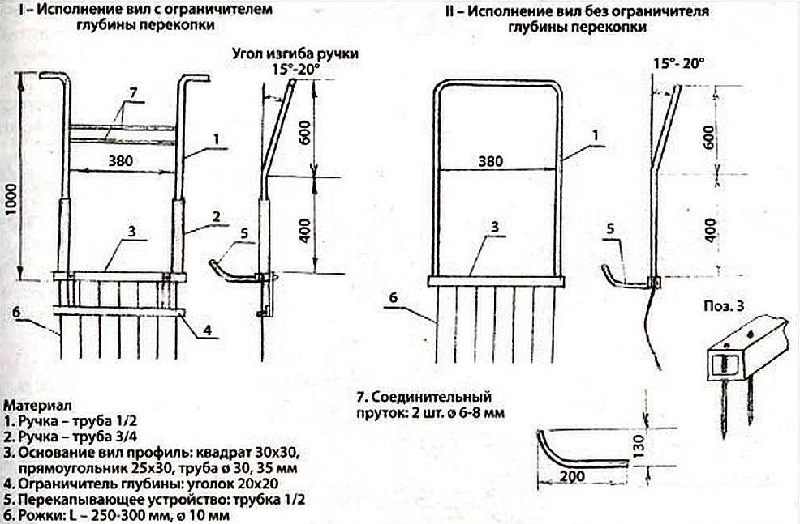

The design of the device consists of several separate parts, which are assembled in turn and then put together:

- They make a ripper (see drawing below) from a rod with a diameter of 12 mm and a length of 67.7 mm, to which 8 rods of the same diameter and a length of 280 mm are welded perpendicularly through equal distances. From above, 2 corners No. 25 are attached perpendicularly, reinforced for rigidity with diagonally welded rods of the same diameter.

- Perpendicularly welded to a pipe 28x25x3 mm and 800 mm long 9 pieces of reinforcement No. 12 with a length of 280 mm each, pre-sharpened and cleaned by a grinder from the edges of rigidity. On the other side of the supporting pipe, they attach perpendicular to the posts of handles from pipes with a diameter of ¾ ", each 1650 mm long. At a height of 1000 mm, they are bent 30 ° in relation to the vertical towards the baking powder, where a pipe of the same diameter and 400 mm long is attached between them. The upper parts of the handles 200 mm long are bent at an angle of 90 ° in opposite directions.

- The pedal is made of 2 pieces of pipes 28x25x3 mm 150 mm long... They are connected perpendicularly at the ends to a pipe ¾ "in diameter and 400 mm long. From the other ends, parallel to the pipe, a piece of reinforcement No. 12 of the same length is welded. At a distance of 200 mm from the first piece of reinforcement, another one is attached parallel to it. From above, at the ends of the rectangular pipe segments, segments of the same pipes 80 mm high each are attached perpendicularly.

- To the sides of the resulting pedal the ripper is bolted.

- The structure is attached to the rest of the potato digger with the help of curtains, some parts of which are welded to the handle posts, and the second to the vertical pipe sections on the pedals

To make this effective manual do-it-yourself potato digger, a drawing is presented below:

Read also:

Conclusion

The manual potato digger is called so by tradition, since many of its modern versions are based on the use of mainly legs. In any case, these tools use the physical strength of a person when working. Reducing the load on it to a minimum, while increasing labor productivity, is the main task of such devices.

To make a productive manual potato digger yourself, you have to make a lot of efforts, but they will surely pay off with easier and even more enjoyable work in the garden.