How to make a two-row potato planter yourself

Owners of farms and small plots know that planting potatoes is a very laborious process. But modern technology makes this work easier. The unit called a potato planter simplifies and speeds up planting many times over. The device is expensive, so many do it yourself.

The content of the article

Double-row potato planter: what is this device

The potato planter is widely used in farms. With its help, the tubers are buried in correct rows and with high productivity.

In addition, the machine applies mineral fertilizers to the soil and pickles vegetables.

Description and characteristics

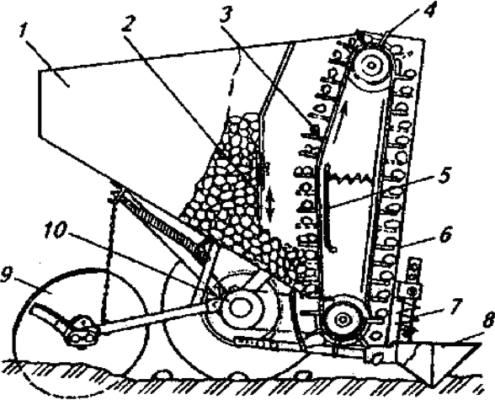

Most of the units have a similar design. Main elements:

- frame with wheels;

- tank for planting material;

- furrow openers;

- drive (often a chain is used to transmit torque);

- sealing discs for filling furrows.

In addition to the functions described, the potato planter regulates:

- landing depth;

- row spacing;

- distance between tubers.

There are models equipped with special fertilizer tanks. Top dressing is carried out simultaneously with planting potatoes.

What is it for

The device is used for planting non-sprouted tubers in any type of soil. With the help of a potato planter, several operations are performed simultaneously:

- make a furrow with a plow;

- potatoes are introduced at a selected distance from each other;

- form beds, filling furrows with earth at a certain angle.

When used correctly, the machine places the tubers at the required depth and in even rows.

What is the advantage over single row

The single-row devices are equipped with one conveyor and a hopper that can hold up to 120 kg. They are usually installed on walk-behind tractor.

Double-row units are used for a mini tractor. Their design provides 2 conveyors for feeding potatoes, and the hopper capacity is up to 250 kg. Such potato planters create 2 furrows at once, which significantly speeds up planting.

How to do it yourself

All tools and materials are pre-assembled and the working site is prepared where welding will be carried out.

Materials and tools

For work you will need:

- plywood sheets;

- channel;

- metal corners;

- fittings;

- drying oil;

- rubber and felt pads;

- steel sheets;

- bolts.

Instruments:

- welding machine;

- Bulgarian;

- drill;

- screwdrivers, pliers, wrenches.

Diagrams and drawings

The tubing is one of the most complex units of the unit, and not all home craftsmen manage to repeat the factory mechanisms on their own.

Interesting! Some farmers advise, instead of installing a mechanized part, placing an assistant on the frame next to the container with tubers, who will manually throw them into the furrows.

There are relatively simple constructions to make. Below are a drawing and a photo of a homemade device.

Step-by-step instruction

How to make a do-it-yourself potato planter:

- The basis of any technique is the frame. All other elements are fixed to it. The two side members are connected by three cross members. The arches are welded to the side members, on which the forks are fixed.

- The volume of the hopper is usually made at 190-220 liters. It is made from 12 mm plywood sheets, which are connected with steel corners and bolts.The hopper is treated with waterproof paint or drying oil. A rubber gasket is installed inside to protect the potatoes from damage.

- The wheel axle and ripper holder are bolted to the frame. For the axis, take a cast-iron or steel thick-walled pipe, into the ends of which pins or spikes are inserted. Then holes are made to install the pins holding the pins. After assembly, the pins are welded.

- For the manufacture of wheels, steel sheets are taken. Wide cylinders are made of them so that the soil does not become very compacted. The wheels are attached to the pins.

- From the edges of the frame, the posts for the sealing discs and the supports of the seed tubes are welded.

- The ripper holder is welded into a square of 2 rods. At the ends of the latter, steel clips are mounted, into which special stands for cultivator-type paws are installed.

- For the manufacture of a sower, a metal pipe with a cross section of 100 mm is taken. The minimum wall thickness is 10 mm. A thick sheet metal furrow cutter is welded from the bottom of the pipe.

For work on slopes, the rear flaps are equipped with a counterweight to increase the landing speed several times.

Description of finished models

For comparison, we present a description of some models.

The Bomet is one of the most common two-row mounted potato planters. The model works with a mini tractor or a tractor equipped with a suspension device. Performs the following functions:

- creates furrows;

- plants tubers;

- spuds the ground;

- creates beds at the desired angle.

The model has an adjustment of the distance between the rows (from 62 to 67.5 cm) and individual tubers (from 29 to 35 cm). Depth of disembarkation is 10-15 cm. The cost of the device is 470-510 dollars depending on the region.

AGROMECH works in tandem with a mini tractor. This is a two-row potato planter from a Polish manufacturer. The machine plants tubers at a depth of 10 to 15 cm, leaving 62.5 cm or 67.5 cm between rows. The distance between potatoes in a garden bed is changed to 29 cm, 32 cm or 35 cm. The model costs 380-400 dollars.

Potato planter planting technology

The minitractor or tractor is placed on a flat surface, a device is attached to it.

Important! The fasteners must comply with the manufacturer's instructions for the specific model.

During operation, adjustment of the following parameters is available:

- immersion depth;

- the angle of attack of the hiller.

Often, before starting work, the field is marked with a special device made of any handle and cross-bar 1.5–2 m long. Stakes are screwed into the cross-bar at a distance of 60–70 cm. The resulting device is carried along the ground, creating strips that will serve as beacons when cutting furrows.

After that, the potatoes are poured into the bunker and planting begins. The distance between individual tubers is 30–40 cm.

It is interesting:

Starch in potatoes: varieties with high and low content in the composition.

Tips

During work, the following recommendations are observed:

- Preliminary check the serviceability of the main parts. At this time, the tractor must be turned off.

- If necessary, use ear plugs or headphones to reduce the negative impact on hearing.

- The device is connected only to tractors with the required size, grip and performance for a specific model of potato planter.

- The equipment is used only for planting potatoes.

- When turning, the gutter beam is raised so that the parts do not deform.

- After completion of work, the device must be cleaned. If necessary, rubbing elements are lubricated.

For quick harvesting from large areas, some farmers use homemade double row potato diggers. They allow you to get tubers from several rows at once.

Conclusion

The potato planter greatly simplifies and speeds up the work. For self-manufacturing of equipment, it is better to use ready-made drawings to minimize the risk of errors.For the device to serve for a long time, it is important to study the recommendations for use.