What are the sheds for grapes and how to make them yourself

Large bunches of grapes are the decoration of any garden. Many summer residents grow grapes under arched awnings or tents - this is convenient and practical. Sheds are erected over the porch, near the walls of houses or in the center of the garden area. The vines intertwine beautifully and turn into green columns. In order for the canopy to serve for a long time, attention is paid to the material of manufacture and the type of construction. What are the sheds for the vineyard and what to look for in the manufacture, we will consider in the article.

The content of the article

Types of canopies for grapes

Sheds are distinguished by material of manufacture and type of construction. Some summer residents prefer metal arches, others prefer wooden arbors.

Made of metal

Metal garden structures are durable and durable. They can withstand heavy loads, are easy to use and maintain. Metal sheds are used by both amateurs and experienced gardeners who grow grapes for the sale and production of wine. The disadvantage of this design is the complexity of manufacturing and installation. Only those who have the skills of welding and special equipment will be able to make a canopy of metal on their own.

A budget and durable option is a canopy made of a shaped pipe and wire. It has a low cost, compared to other metal structures, it is easy to manufacture. Summer residents also install metal structures in the garden. The material is lightweight, has an aesthetic and attractive appearance, lends itself well to cutting and does not bend at the same time. With the help of metal tiles, they create original awnings that will decorate any summer cottage.

Made of wood

Wood is used to make simple and complex garden structures. It can be a traditional canopy in a classic style or austere minimalist one. A common option is a boardwalk made of wooden stakes and slats. The material has a pleasant natural texture and beautiful appearance, accessibility and ergonomics. The tree is laconic, will fit into spacious and compact garden areas, the manufacture of such awnings does not require a welding machine.

However, wooden home sheds are less practical than metal ones. To protect against decay and damage, the tree is periodically treated with antiseptic agents, covered with paint and varnish. The material deteriorates from high humidity and temperature changes. Wood weighs more than metal and loses its appearance faster.

Attention! The ideal option for making a canopy is combined frame systems, where the supports are made of metal, and the rest of the elements are made of wood. Such designs are beautiful and reliable.

Arch-shaped tent

The arched awnings are a sturdy trellis with a curved roof. A structure is made of a shaped pipe, wire, metal arcs and other materials. Arched awnings are popular and aesthetic, you can make them yourself or buy ready-made ones. A semicircular or curved roof protects the vines from wind, rain and snow. The vines twine around the arches, which looks very beautiful and complements the landscape design.

The disadvantage of cooking sheds is that summer residents have to direct the vine so that it always grows around the outer perimeter.If this is not done, the vines braid the bottom of the arch, the canopy loses its appearance, and ripe bunches are difficult to look for in the thickets.

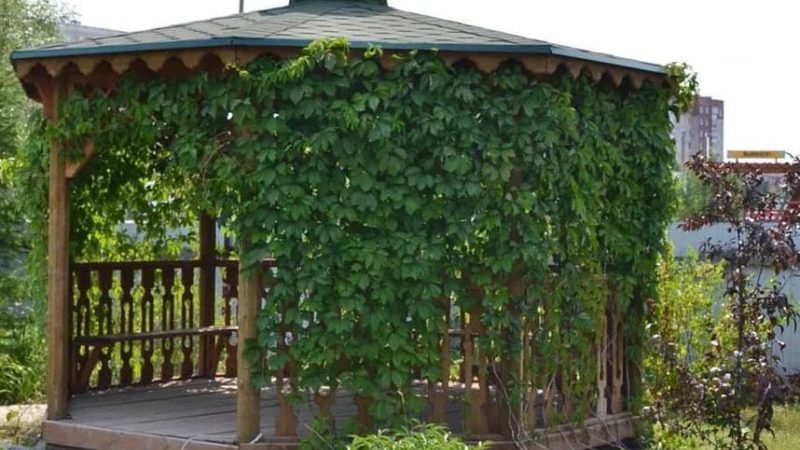

Alcove

A grape gazebo is made of frame metal or wooden structures... Green vines twine around the gazebo, giving it an original appearance. The frame can be round, square, polygonal, depending on the personal preference of the gardener. The roof is solid or lattice, most often it is made of light wood. The gazebo will become a favorite place to relax or receive guests. It is installed on the west or south side of the garden plot, since grapes develop poorly from the north.

Attention! The gazebo can be temporary - such structures are assembled and removed as needed - or capital - an option with a solid foundation and support. Temporary gazebos are mobile and lightweight; as a rule, gardeners clean them for the winter. Capital ones are equipped with furniture, a fireplace or a stove, they serve as a resting place.

How to make a canopy for grapes with your own hands

The cost of grape sheds - from 10,000 rubles. and higher. Many gardeners prefer to make arches or gazebos on their own. This saves money and allows you to create an original design according to personal preference.

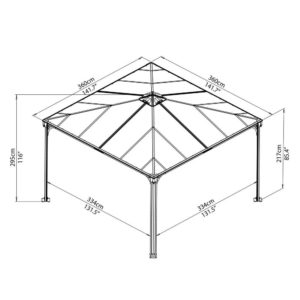

How to weld a tent from a metal profile pipe

First, a detailed drawing is prepared with the dimensions of all elements. This helps to select materials and calculate the cost of the structure. They also prepare tools: a welding machine, a hammer drill, a construction tape, sand and cement. For manufacturing, use steel pipes of square or rectangular cross-section and metal wire. The pipes are welded into a solid frame.

Attention! For supports, square pipes are most often used, since they are more susceptible to stress. For the manufacture of other elements - rectangular. The design is lightweight due to the even distribution of weight.

Further, they are determined with the type of frame. If this is the first experience in the manufacture of awnings, it is recommended to pay attention to square or rectangular frames. They are the simplest and do not require any special training. Polygonal frames imply many joints at the corners, only professionals can make them exactly and correctly. Before welding, pipes and supports are coated with an anti-corrosion agent to protect the canopy from rust.

A simple vine tent is made like this:

- Supports are installed - shaped pipes 2.5-3.5 m long.They are concreted parallel to each other at a distance of 2 m.

- Holes are made in them for wire at a distance of 30 cm from each other.

- Pull it every 0.5 m - get horizontal rows of weaving, tighten them vertically.

Wooden canopy for grapes

A complex tool is not required to assemble wooden awnings; it is enough to have wooden planks and bars and ordinary nails on hand. The frame can be round or square, the roof - vaulted or in the form of a decorative lattice, conical or polygonal. For manufacturing, a rounded log with a diameter of 10-20 cm and a profiled bar are used. Suitable species are ash, oak, pear, larch, birch.

The lumber is laid out and dried for 5 days, the surface is treated with sandpaper and impregnated with a bactericidal solution to protect it from damage.

Canopy making process:

- A drawing is drawn up, which indicates the size of the beams and supports, the step of installing the beams, the length of the support pillars.

- Choose a place to place the canopy and remove the topsoil.

- Dig holes for supports with a depth of 90 cm.

- Side piles are mounted using concreting.

- The vertical pillars are tied around the perimeter with wooden bars and left for a week to strengthen.

Rules for planting and growing grape vines under a canopy

To make the grape shed in the courtyard of a private house look beautiful, summer residents take time correct planting of grapes and carrying out agrotechnical works.

How to plant correctly

Have a canopy with grapes in an elevated area... The soil is dug up and leveled, debris and large stones are removed. Grapes are planted at a distance of 20-30 cm from the frame. The distance between plantings should be at least 100 cm, otherwise in the future the vines will interfere with each other.

Planting pit depth - 50 cm... 2-3 weeks before planting it fertilize biohumus or humus. The grapes do not tolerate waterlogging, therefore, a drainage layer 20 cm deep from fine sand and gravel is prepared at the bottom of the pit.

The seedling is placed in a hole, the roots are straightened at an angle, sprinkled with earth and tamped. The shoot is tied to the lower part of the frame, watered with warm water. In this case, the canopy serves as a supporting structure. In summer, when the length of the shoot is 30 cm, summer residents tie up the green parts of the plant.

It is interesting:

Grape care and formation

The first 2-3 years, the grapes are formed so that the young vines are at the top, and the beginning of the sleeves is at the bottom. In subsequent years, summer residents remove old and damaged processes. If this is not done, the vine will be "shaggy" and yield will decrease. Grapes are formed in early spring (before the onset of sap flow) or in autumn (a month before the onset of frost). The procedure improves the appearance of the vines.

Water the grapes every 2-3 weeks. Lack of water leads to the fact that the roots, in search of moisture, grow strongly and take it away from other plants. In addition to watering, grape leaves and vines are sprayed with water from a spray bottle. This is especially important for grapes that grow under a solid roof.

Attention! Under the canopy, they show a stable yield of the varieties Moskovsky resilient, Vostorg, Michurinsky. They are hardy and rarely get sick.

Conclusion

For the manufacture of vine sheds, wood or metal is used. Wooden structures look aesthetically pleasing, but they require constant maintenance and protection from fungi. Metal ones are durable, but their manufacture requires welding equipment and skills in working with it. A gazebo or archway will become a favorite resting place, especially if you regularly shape the vines and guide their growth.